Inventory management is the practice of ordering, storing, and using a company's inventory. It encompasses raw materials, components, and finished goods, including management of warehouse stock. Effective inventory management is critical for balancing the costs of inventory against the need to fulfill customer orders promptly and completely.

The Inventory Management Challenge

Inventory represents a significant investment for most businesses, often accounting for 20-30% of total assets. The fundamental challenge in inventory management is finding the right balance:

- Too Much Inventory: Ties up capital, increases storage costs, risks obsolescence and damage

- Too Little Inventory: Risks stockouts, lost sales, customer dissatisfaction, and emergency expediting costs

The goal of inventory management is to minimize the total cost of inventory while maintaining adequate stock to support sales and operations.

ABC Analysis: Prioritizing Your Inventory

ABC analysis is a fundamental inventory management technique that classifies inventory items based on their importance and value. This method follows the Pareto Principle: roughly 20% of inventory items account for 80% of the value.

ABC Classification

- Class A Items (15-20% of items, 80% of value): High-value, high-turnover items requiring tight control

- Track inventory frequently (weekly or daily)

- Maintain accurate records

- Keep lower safety stock levels

- Use more sophisticated forecasting methods

- Class B Items (30% of items, 15% of value): Medium-value, medium-turnover items

- Track inventory moderately (monthly)

- Use standard reorder points

- Maintain moderate safety stock

- Use standard forecasting methods

- Class C Items (50-55% of items, 5% of value): Low-value items

- Track inventory less frequently (quarterly)

- Use simplified ordering methods

- May use fixed reorder quantities

- Lower management attention required

Just-In-Time (JIT) Inventory

Just-in-Time is an inventory management strategy that aligns raw material orders with production schedules. Instead of maintaining large safety stocks, inventory is ordered and received only when needed.

JIT Benefits

- Reduced inventory carrying costs

- Lower warehouse space requirements

- Reduced waste and obsolescence

- Improved cash flow

- Higher inventory turnover

JIT Challenges

- Requires reliable suppliers with fast delivery

- More vulnerable to supply disruptions

- Less flexibility for demand variations

- Higher order frequency and costs

- Requires strong supply chain coordination

Safety Stock and Reorder Points

Safety stock is buffer inventory held to protect against demand uncertainties and supply variability. Determining optimal safety stock levels requires balancing holding costs against stockout risks.

Calculating Safety Stock

A basic safety stock formula:

Safety Stock = Z × σ × √LT

Where:

- Z = Service level factor (e.g., 1.645 for 95% service level)

- σ = Standard deviation of demand

- LT = Lead time in periods

Reorder Point

The reorder point is the inventory level at which a new order is placed:

Reorder Point = (Average Daily Demand × Lead Time) + Safety Stock

Demand Forecasting for Inventory

Accurate demand forecasting is essential for proper inventory management. Poor forecasts lead to either excess inventory or stockouts.

Forecasting Methods

- Quantitative Methods:

- Time Series Analysis: Using historical data patterns

- Trend Analysis: Identifying upward or downward trends

- Seasonal Decomposition: Separating seasonal patterns from trends

- Regression Analysis: Correlating demand with external factors

- Qualitative Methods:

- Expert Opinion: Input from salespeople and managers

- Customer Surveys: Direct feedback on future demand

- Market Research: Industry trends and competitive analysis

Economic Order Quantity (EOQ)

The Economic Order Quantity is the order size that minimizes the total cost of inventory, balancing ordering costs against holding costs.

EOQ Formula

EOQ = √(2DS/H)

Where:

- D = Annual demand (units)

- S = Ordering cost per order

- H = Holding cost per unit per year

EOQ Interpretation

- Orders should be placed when inventory reaches the reorder point

- Each order should be for the EOQ quantity (or close to it)

- As holding costs increase, order quantity decreases

- As ordering costs increase, order quantity increases

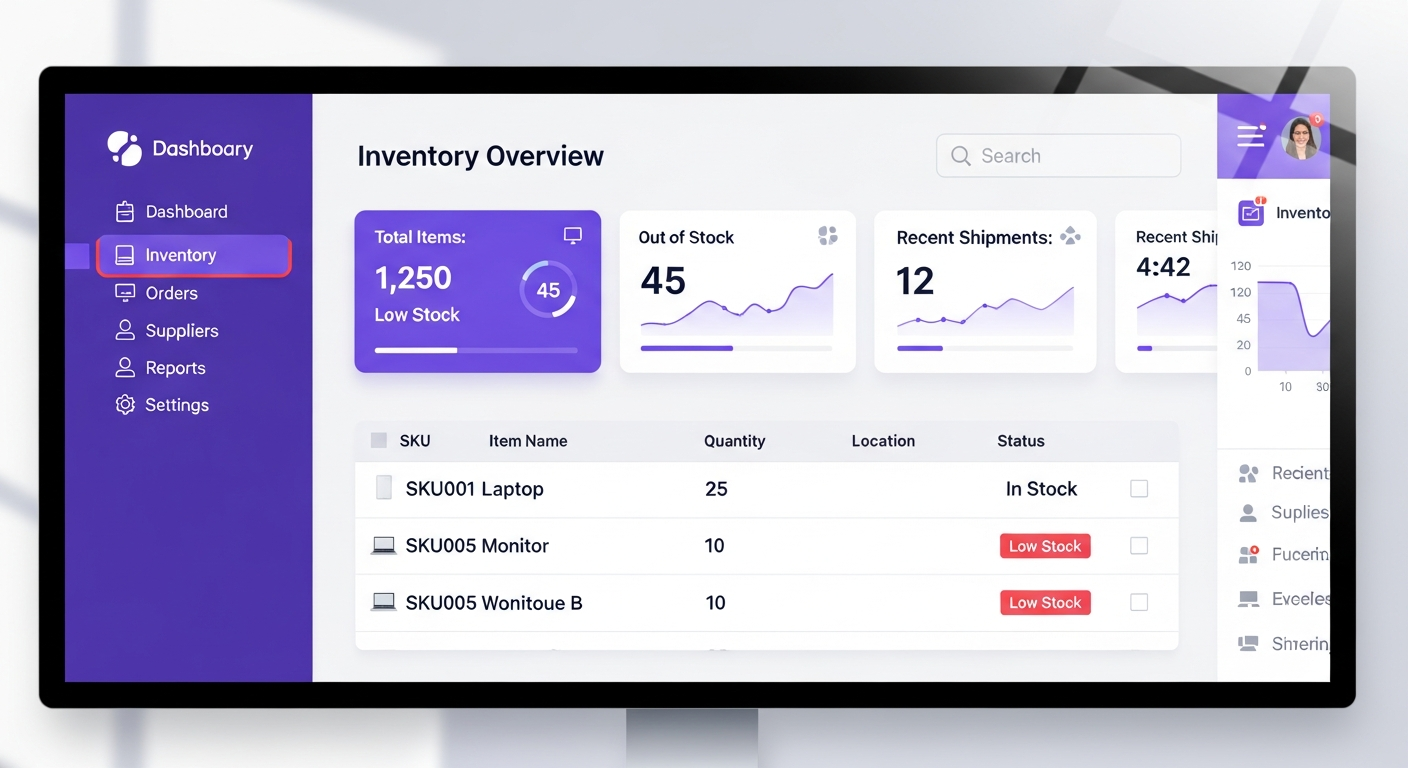

Warehouse Management Systems (WMS)

Modern inventory management relies on sophisticated software systems to track stock levels, manage orders, and optimize warehouse operations.

Key WMS Features

- Real-time inventory tracking

- Automated reorder points and suggestions

- Barcode and RFID integration

- Lot and serial number tracking

- Multi-warehouse inventory management

- Demand forecasting and analysis

- Receiving and put-away optimization

- Pick and pack automation

- Cycle counting and physical inventory management

- Integration with ERP and accounting systems

Inventory Valuation Methods

How inventory is valued affects financial statements and tax calculations. Common methods include:

Valuation Approaches

- FIFO (First In, First Out): Older items are valued as sold first

- More realistic for most industries

- Higher profit in inflationary periods

- Matches physical inventory flow

- LIFO (Last In, First Out): Newer items are valued as sold first

- Better tax benefits in inflation

- May not match actual physical flow

- Weighted Average Cost: Uses average cost of all units

- Simple and practical

- Smooths out price fluctuations

- Specific Identification: Tracks actual cost of each unit

- Most accurate for high-value items

- More time-consuming

Cycle Counting and Physical Inventory

Regular physical counting of inventory is essential to ensure accuracy and identify discrepancies.

Cycle Counting

- Continuous Process: Count a portion of inventory regularly (daily or weekly)

- Class A Items: Count most frequently (monthly or quarterly)

- Class B Items: Count periodically (quarterly or semi-annually)

- Class C Items: Count annually

Physical Inventory

- Complete count of all inventory, typically annually

- Often performed during slower business periods

- Reconciles book inventory with actual stock

- Identifies theft, damage, or record errors

Inventory Performance Metrics

Measuring inventory performance helps identify areas for improvement:

- Inventory Turnover: Cost of Goods Sold ÷ Average Inventory

- Higher turnover indicates efficient inventory management

- Industry-specific benchmarks vary widely

- Days Inventory Outstanding (DIO): 365 ÷ Inventory Turnover

- Average number of days inventory is held

- Lower is generally better

- Carrying Cost: Total cost to hold inventory

- Storage, insurance, obsolescence, capital costs

- Typically 20-30% of inventory value annually

- Stockout Rate: Percentage of orders that cannot be fulfilled immediately

- Target varies by industry and customer expectations

- Fill Rate: Percentage of customer demand met from inventory

- Higher is better

- Often 95-99% target

- Inventory Accuracy: Variance between recorded and actual inventory

- Target is typically 98% or higher

"Inventory management is not about holding the most stock; it's about having the right stock at the right time. This requires planning, forecasting, and continuous adjustment."

Best Practices for Inventory Management

- Demand Planning: Invest in accurate forecasting to reduce safety stock needs

- Supplier Collaboration: Work with suppliers to reduce lead times and improve reliability

- Technology Implementation: Use WMS and ERP systems for visibility and automation

- Regular Audits: Conduct cycle counts and reconciliations to maintain accuracy

- Obsolescence Management: Identify and manage slow-moving or obsolete items

- Continuous Improvement: Regularly analyze metrics and adjust strategies

- Cross-Functional Collaboration: Coordinate between sales, operations, and finance

- Supplier Diversification: Reduce risk by working with multiple suppliers

Conclusion

Inventory management is a critical component of supply chain excellence that directly impacts profitability and customer satisfaction. By implementing proven strategies such as ABC analysis, JIT, safety stock optimization, and demand forecasting, companies can significantly reduce inventory costs while improving service levels. The key is to find the right balance for your business—one that maximizes cash flow and efficiency while ensuring product availability. With modern inventory management systems and a commitment to continuous improvement, organizations can transform inventory from a cost burden into a competitive advantage.